Mucilage

Adhesives, also known as adhesives, are substances that can bond two or more materials (substrates) together, forming adhesion on their surfaces through physical or chemical reactions to achieve the purpose of combination. Their components can be natural or synthetic, including resins, rubber, polymers, etc. The main function of adhesives is to provide adhesion and bonding strength to achieve a tight bond between materials.

In addition, adhesives can also play a variety of auxiliary functions such as sealing, waterproof, insulation, shock absorption, impact resistance, and are widely used in various industrial and daily applications, such as automobile manufacturing, electronic appliances, medical devices, construction and decoration.

Non-woven material

Non-woven fabric is a kind of woven fabric without spinning, by the textile short fiber or filament direction or random arrangement into a fiber network structure, and the use of mechanical, thermal bonding or chemical reinforcement of the fabric. It has good filtration, moisture absorption, protection and insulation properties, and is widely used in medical and health (such as disposable mouth sets, protective clothing, surgical cloth, etc.) and agriculture (such as agricultural summer cover cloth, anti-grass cloth, etc.) and other fields.

Organosilicon material

Silicone material is a kind of polymer compound with skeleton structure, which has excellent heat resistance, cold resistance, weather resistance, aging resistance and electrical insulation properties, and is widely used in many fields. Its main functions include sealing, insulation, waterproof, high temperature resistance and elastic material functions. In the electronic and electrical industry, it is used to manufacture cable insulation, potting adhesives and thermal grease for electronic components; In the automotive industry, it is used in the manufacture of sealing gaskets, lamp protection and engine seals.

High functional resins and polymers

High-functional resins and polymers are synthetic materials with special physical, chemical or mechanical properties that have been modified and optimized to meet specific high-performance requirements. They are mainly used to provide excellent strength, heat resistance, chemical resistance, wear resistance and electrical insulation. In the aerospace sector, these materials are used to make lightweight and high-strength fuselage components and composites; In the electronics and electrical industry, for the production of high-performance insulation materials, printed circuit boards and electronic packages; In the automotive industry, it is used in the manufacture of high-temperature engine parts and lightweight body materials; In medical devices and instruments, it is used to produce biocompatible implants and medical devices.

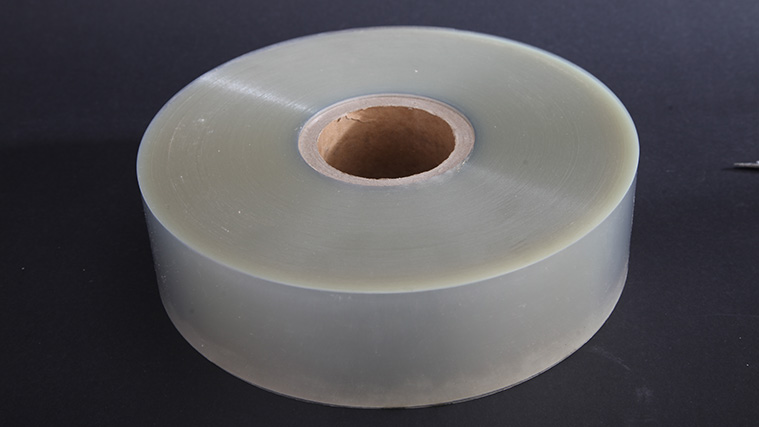

Thin films and porous materials

Thin films and porous materials refer to materials with a thickness of micrometers or less, or materials that contain a large number of small pores in their structure. Their main function is to provide isolation, filtration, ventilation, insulation and transmission functions. Thin film materials are commonly used in the electronic display, solar cell and packaging industries to enhance product performance and functionality due to their thin, transparent and conductive properties. Porous materials are widely used in filtration, catalysis and biomedicine, enabling efficient separation, reaction and tissue engineering through their excellent permeability, adsorption and biocompatibility.

Coating

Coating refers to a layer of functional substances applied to the surface of a material that has the effect of improving surface properties. Coating technology plays an important role in modern industry and daily life, and by applying different types of functional substances to the surface of materials, it can significantly improve their performance. Anti-fog coating, hydrophilic coating and hydrophobic coating respectively show unique advantages in preventing water vapor condensation, absorbing and diffusing water, and water repellent protection, and are widely used in eyeglass lenses, architectural glass, electronic equipment shell and other fields. The diversification and efficiency of coating technology is increasingly becoming a key factor in enhancing product competitiveness and user experience.